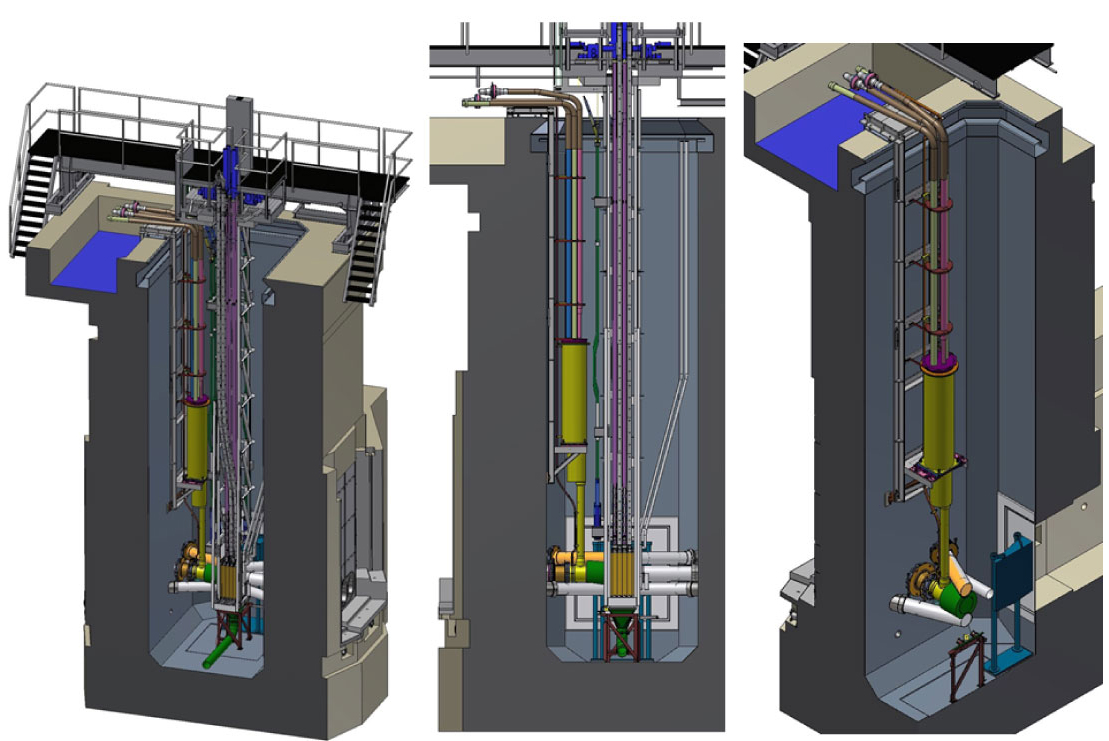

Equipment For Special Purpose, Common Facilities & Others

Nuclear power plant equipment is broadly divided into Main Power Generation Equipment, Balance of Plant(BOP), and Spare Parts. Large companies such as Doosan Enerbility and the U.S. firm Westinghouse manufacture Main Power Generation Equipment like reactors, turbines, generators, and steam generators, while BOPs and Spare Parts areproduced by small and medium-sized enterprises. Moojin Keeyeon Co., Ltd. primarily manufactures BOP and Spare parts, and it has notably exported six BOP packages to the UAE Barakah Nuclear Power Plant, the highest number among South Korean SMEs.

Customer companyintroduction >

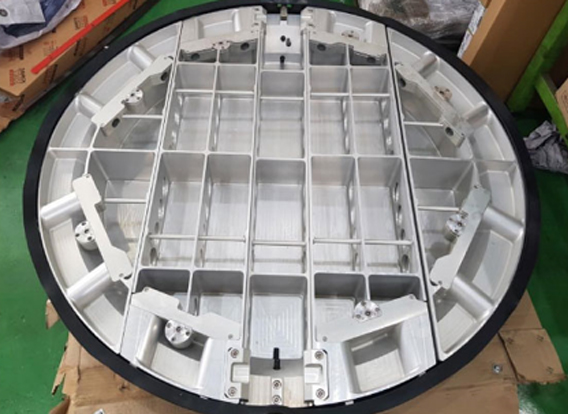

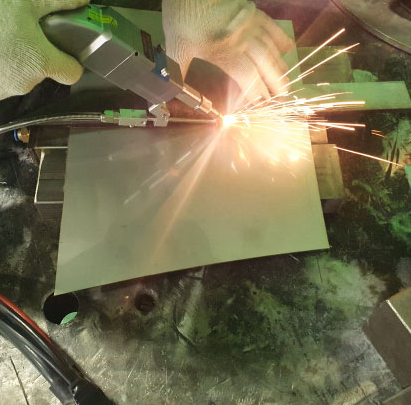

Moojin Keeyeon Co., Ltd. operates a world-class Quality Assurance system in

the nuclear sector, excels in specialized and precision machining, and possesses advanced

welding technology that is recognized internationally, based on our extensive experience.

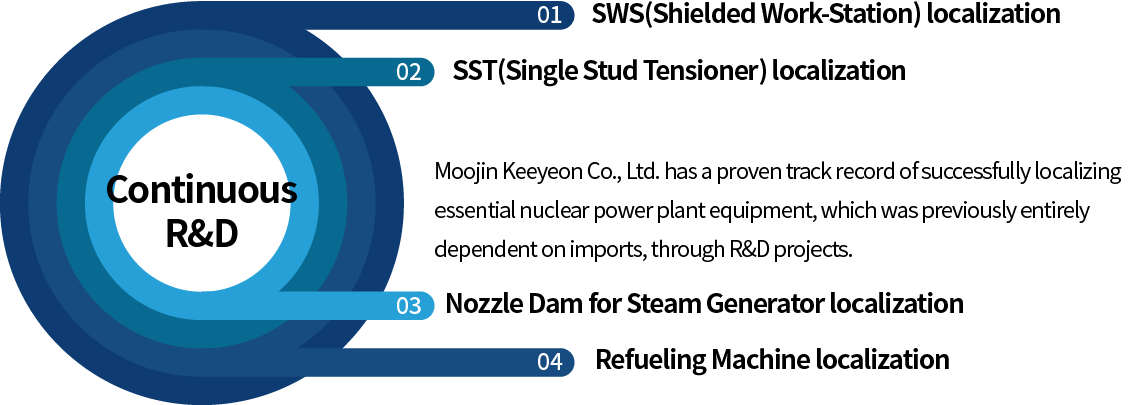

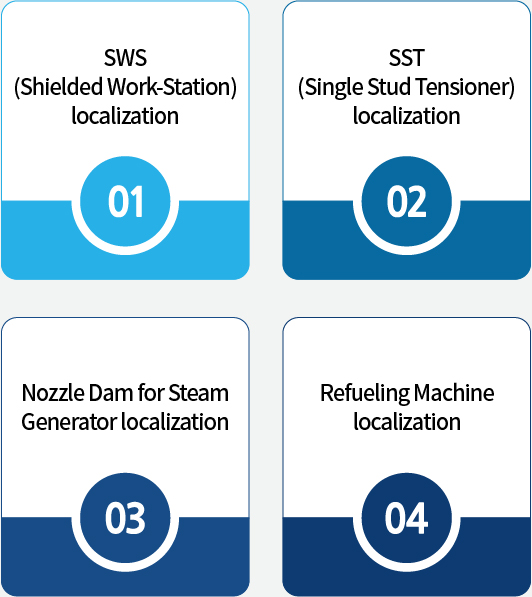

Moojin Keeyeon Co., Ltd. has a proven track record

of successfully localizing essential nuclear

power plant equipment,

which was previously entirely

dependent on imports, through R&D projects.

Moojin Keeyeon Co., Ltd. has participated in the development of next-generation nuclear power plants (SMR, MMR, iSMR) and the development of casks for transporting spent fuel, and is preparing for the future.